Participants successfully completing the program will be able to:

-

Industry trends driving increased use of highly-sensitive ESD class 0 components

-

The leading cause of ESD failures in the electronics industry today

-

Critical factors in a total control system approach for ESD class 0

-

The shift in thinking required about control methods for ESD class 0

-

The limitations of conventional ESD control methods with examples

-

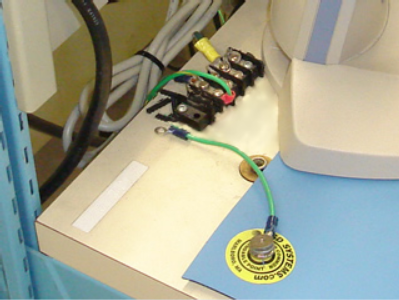

Examples of mitigation techniques to control ESD class zero risks

-

The key issue of Charged Device Model ESD failure for class 0

-

The critical change in ESD control design for class zero

-

Additional requirements of ESD control in a cleanroom environment

-

The impact of class 0 requirements on ESD audit metrics

-

ESD metrics as management tools

-

ESD metrics as management tools

-

A ten step process in manufacturing to become class zero ready

-

The time and effort required to develop a robust ESD class 0 system